, the amount of viable problem microorganisms from the products is approximated at different time intervals by calculating the focus of cfu per mL with the plate depend method. A style and design for validating neutralization would incorporate the treatment groups as explained underneath Validation of Neutralization Methods—Restoration Comparisons.

The aim of bioburden testing should be to measure the entire range of practical micro-organisms (complete microbial count) with a health care unit before its final sterilization right before implantation or use.[two]

This procedure is applicable to the fabric been given and tested in the standard Control Office. This procedure is not really relevant for substance gained and tested somewhere else.

DBP ranges in ingesting h2o could be minimized through the use of disinfectants such as ozone, chloramines, or chlorine dioxide. Like chlorine, their oxidative Homes are sufficient to damage some pretreatment device operations and have to be eradicated early inside the pretreatment approach. The complete elimination of some of these disinfectants is often problematic. As an example, chloramines may perhaps degrade through the disinfection process or for the duration of pretreatment elimination, thus releasing ammonia, which consequently can have around to your finished drinking water. Pretreatment device functions has to be intended and operated to sufficiently clear away the disinfectant, ingesting drinking water DBPs, and objectionable disinfectant degradants. A significant issue can occur if unit functions intended to remove chlorine were, with no warning, challenged with chloramine-that contains drinking drinking water from a municipality that had been mandated to cease utilization of chlorine disinfection to comply with ever tightening EPA Consuming Drinking water THM specifications.

Overall flexibility, cost and time are crucial conditions in evaluating choices inside a ‘Establish or obtain’ choice to your technology.

The method is usually regarded as validated if all teams present copious growth in just seven times for all microorganisms.

The bioburden testing methods isolate and enumerate feasible microorganisms prior to sterilizing any components and products. These testing methods have a number of uses in several laboratories, which happen to be as follows:

For drug commodities, both protection and performance are crucial. On the one particular hand, drug protection is set by whether the chemical composition and written content from the drug are Safe and sound, and However, drug basic safety is decided by whether or more info not the drug is contaminated by microorganisms. There are various types of microorganisms. Just after contaminating medication, They might decompose the powerful substances of drugs, leading to lessened or lost efficacy.

The products less than test is taken into account non-inhibitory to microorganism beneath the outlined test condition if the subsequent problem is achieved.

It ought to be regarded that there is no solitary method that's capable of detecting most of the prospective microbial contaminants of the h2o process. The methods utilized for microbial checking really should be able to isolating the figures and types of organisms which have been deemed substantial relative to in-process system control and product impact for every unique procedure. Several conditions need to be considered when selecting a method to observe the microbial written content of the pharmaceutical drinking water method.

Very similar Restoration involving the test team along with the peptone group demonstrates satisfactory neutralizer efficacy; equivalent recovery in between the peptone group and the viability team demostrates adequate neutralizer toxicity.

• After the here complition of incubation period of time colonies areAfter the complition of incubation period colonies are

if possible rabbit or horse plasma with or without having suited additive. Incubate inside of a water bath at thirty°C to

Validation is the procedure whereby substantiation to the high amount of assurance that a certain process will constantly generate a product conforming to an established list of excellent characteristics is obtained and documented. Just before And through the incredibly early levels of validation, the critical process parameters and their running ranges are recognized.

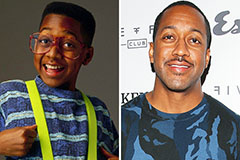

Jaleel White Then & Now!

Jaleel White Then & Now! Mr. T Then & Now!

Mr. T Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!